How To Prime Engine After Rebuild

The need to prime number a fresh engine before initial offset-up isn't a large undercover.

It's likewise a skillful idea to prime the oil pump before information technology is installed. Experts concur.

The folks from Melling offer this insight:

"Although oil pumps are made with close tolerances, oft they aren't cocky-priming. Unprimed, an oil pump could run for several seconds before picking up oil. Or worse, it might not pick up oil at all. This could lead to early wear of the oil pump and the engine bearings."

Priming (and testing) the pump prior to installation is easy.

You can simply dip the pump with a pickup fastened in a container of clean oil and turn the driveshaft by paw until oil is released from the pump. Basically, you now know it works. Some folks adapt an oil PSI gauge to the pump in order to cheque pressure, but it's certainly not essential.

Next, drain the oil and install the pump on the engine.

One time the engine is assembled, you should prime the oiling system. That's accomplished with a pump priming tool. Yeah, it's easy plenty to build your ain by using an old distributor shaft and body, but the tools are available right hither at Elevation Racing and for the most role, they're very affordable.

Using a typical Chevy as an instance, the pump primer is inserted into the benefactor pigsty and, in turn, engages the oil pump drive shaft. At this point, the top of the shaft is chucked into a iii/8-inch, or preferably, a ½-inch drill and spun in the direction of distributor rotation until the engine develops total pressure for approximately thirty seconds. The crank is rotated approximately a half-turn and the process is repeated. Those are the nuts.

At that place are a couple of unlike primer styles out in that location.

The simple ones for Chevys such as the Moroso 62200 tool shown in the accompanying photos will likely only prime the pump. Yous won't be able to pressurize the height cease of the engine. Tools such as the Melling PT13 or the Stef's (B&B Operation) 65100 contain an aluminum bushing that seals the oil gallery. That in plough directs oil to the cam bearings, lifters, pushrods and finally the rocker arms.

With these more than refined tools, you tin can actually witness the oil every bit information technology comes out of the rocker arm(s).

A note here regarding drill motor size: A wimpy 3/8-inch drive setup might be suitable for an application that uses super low-cal oil, only if yous're into (for example), 20W-forty lube, you'll likely need something more than substantial.

While y'all're at information technology, it'south a expert thought to very slowly rotate the engine a total turn (by hand) while priming the oiling arrangement. Although this process might have an extra set of easily (buddy, married woman, neighbor, kid), it but adds insurance that everything is properly lubricated.

The bottom line here is, you never want to allow the crank main journals, rod journals, or cam journals to ride directly on dry begetting surfaces.

A film of lubricant is needed. Otherwise, damage can occur in a nanosecond.

In the terminate, priming tools are inexpensive and readily available.

For a closer wait at the three unlike conventional Chevy jobs mentioned in the text, check out the accompanying photos.

…

Distributor-less Priming

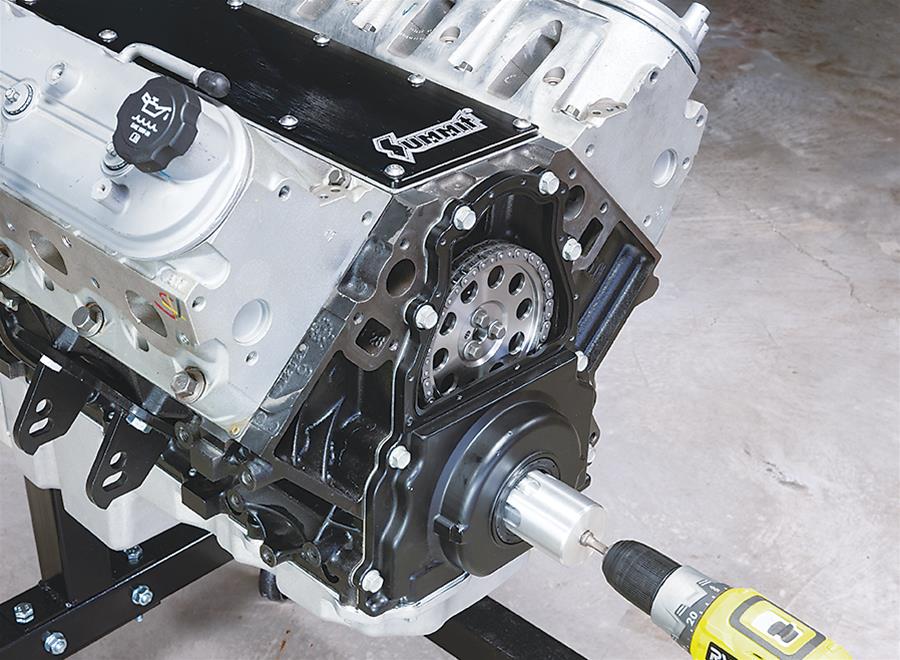

Apparently, belatedly model engines such as the Chevy LS are distributor-less. That means you tin can't prime them with a drill hooked up to a priming tool.

For these engines (those fitted with a removable oil pump drive gear), Pinnacle Racing has come up up with a special oil primer socket. It only slips over the crank. You hook upwardly a drill and manually spin the pump, which in plough, lubes the engine. It's available under part number SUM-900330.

Source: https://www.onallcylinders.com/2020/04/22/oil-pump-primer-tech-starting-up-your-new-engine-the-right-way/

0 Response to "How To Prime Engine After Rebuild"

Post a Comment